HS PH13 Hot Work Die Steel

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Jiangsu,China

- Packaging

- N/A

- Delivery

- 30-45 Days

Specifications

HS PH13 Hot Work Die Steel

The HS hot die steel h13 is also a good material for many customers.

As modified hot work die steel with high roughness and high isotropy, HS PH13 with its molding die design optimizes the alloy element ratio on the basis of traditional H13, reduces the content of

harmful elements such as P and S, so that hot die steel H13 has good thermal stability and thermal fatigue resistance.

Chemical properties of HS PH13

Steel Grade C Si Mn P S Cr Mo V

HS PH13 0.35~0.40 1.00~1.20 0.40~0.60 ≤0.010 ≤0.002 4.80~5.20 1.20~1.40 0.90~1.00

Features of HS PH13

With electro slag remelting, diffusion annealing process and ultrafine heat treatment, it has good microstructural homogeneity and finely dispersed carbides.

Good Tempering performance, high toughness, high high-temperature strength, good thermal stability and thermal fatigue resistance.

High isotropy, aspect ratio ≥0.8.

Annealing hardness≤230HB, quenching hardness 51~55HRC, tempering hardness 46~50HRC.

Mechanical Properties of HS PH13

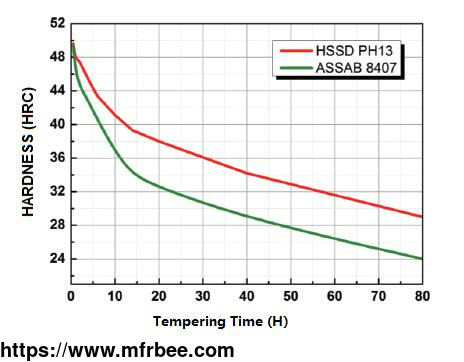

Good Thermal Stability of HS PH13

Tempering Curve of HS PH13

Recommend Heat Treatment of HS PH13

If you want to know more about hot die steel h13 price, please contact us.

As a reliable die steel supplier, we will do our best to provide more types of h13 steel for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai