HS S350 Hot Work Die Steel

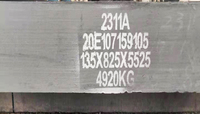

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Jiangsu,China

- Packaging

- N/A

- Delivery

- 30-45 Days

Specifications

HS S350 Hot Work Die Steel

HS S350 steel is improved Cr-Mo-V hot work die steel. The special composition design makes it have high high-temperature strength and thermal fatigue resistance. The overall performance is better

than traditional H13 steel. It is widely used in die casting molds, hot extrusion dies, hot punching dies, hot forging dies, etc.

Chemical properties of HS S350

Steel Grade C Si Mn Cr P S V Mo

HS S350 0.35~0.40 0.10~0.30 0.40~0.60 4.90~5.40 ≤0.015 ≤0.002 0.40~0.65 1.80~1.90

Application of HS S350

Suitable for medium and large molds of die-casting, hot forming, hot forging, hot extruding with aluminum/magnesium material.

Features of HS S350

As one of die steel manufacturers, we provide this kind of hot work die steel, whose hardness after heat treatment is comparable to that of SUPER H13 steel, while the toughness and polishing

performance are more than twice of H13.

High temper softening resistance, thermal fatigue resistance, thermal melting loss resistance., etc.

High impact toughness and high isotropy.

Recommend Heat Treatment of HS S350

Heating Temperature/℃ Cooling Way Hardness (HRC) Tempering Temperature/℃ Tempering Numbers Hardness (HRC)

Preheating Last Heating

800~840 1010~1040 Oil quenching/ / gas quenching 54~58 560-600 ≥3 47~53

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai