Ring / Cylinder Forging Component

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Jiangsu,China

- Packaging

- N/A

- Delivery

- 30-45 Days

Specifications

Ring / Cylinder Forgings Component

Ring forgings are ring-shaped objects in which external force is applied against the metal blank and transform it by plastic deformation. This force is typically achieved through the use of hammer

or pressure. The forging process creates a fine grain structure and improves the physical properties of the metal. Ring forgings can be seen everywhere in daily life.

Cylindrical parts are an important type in the open forging industry and are important component of products such as pressure vessels and cracking reactors. The forged steel round bar can be

produced according to the drawings and requirements provided by the customer. The surface of the forgings is clean and has small machining allowance.

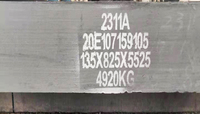

Main parameters Ring / Cylinder

Ring:Outside diameter≤Φ850mm Cylinder:Outside diameter≤Φ850mm

Common technical standards Ring / Cylinder

Ring: NB/T47008~47010

Cylinder: GB/T3077 EN10083 EN10085 JB/T6395

Typical steel grades Ring / Cylinder

Ring: #20, #35, 16Mn, 15CrMo, 1.25Cr-0.5Mo, 2.25Cr-1Mo, 2.25Cr-1Mo-0.3V, 12Cr2Mo1V, 21CrMo10, 0-1Cr8Ni9(Ti), 1Cr17Ni2, 304(L), 316L(N), 321, 347, 00Cr19Ni13Mo3, 00Cr22Ni5Mo3N

Cylinder: 18CrNiMo7-6, 17CrNiMo6, 20CrNiMo, 20CrNi2Mo, 20CrMnMo, 20CrMnTi, 34CrNiMo6, 30CrNiMo8, 40CrNiMo, 35CrMo, 42CrMo

Applications Ring / Cylinder

Gears, wheels, etc. for port machinery and marine machinery. Pressure vessel forgings for chemical machinery

As a die steel supplier, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai