Rotary Vacuum Filter

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Pre-coating Vacuum Filter System

HVD-PVF-P series pre-coating vacuum filter works on the same principle as the general rotary vacuum filter in sugar industry . The main difference of working of rotary drum filter is the filter aid

(such as diatomite, perlite, etc.) precoating before filtering. When in uses of rotary drum filter, the filter aid in the tub under the effect of vacuum suction, to form the required thickness of

the coating outside the drum surface, then feed the material, under the effect of vacuum suction, the separation of the filtrate through precoating and filter cloth, via the absorption liquid tube,

fluid pipe, gas-liquid separator, and the solid particles are intercepted by the precoating. The filter aid surface is scraped by the automatic scraper feeding. When the residual thickness of the

pre-coating is about 10mm, the pre-coating shall be reapplied for the next working cycle.

As filter rotary manufacturers, we offer the best rotary drum filter price of pre-coating vacuum filter system.

Pre-coating Rotary Vacuum Filter System Features

Rotary vacuum filter manufacturers provides personalized design to meet the needs of different customers.

Precoating technology is used in rotary drum filtration to make the filtrate more clear.

Automatic scraper discharge, high filtration efficiency.

The drum surface can be sprayed with and good washing effect.

Series of process equipment, easy to install and use.

Rotary vacuum filter manufacturers have superior production environment, simple and convenient operation.

Belt Vacuum Filter

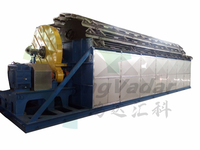

HVD-BFV-P series belt rotary vacuum drum filter is the continuous rotary vacuum filter for continuous suction filtration, dewatering, and automatic unloading under the action of vacuum. The vacuum

drum filter is especially suitable for concentration filtration and dewatering of materials with low solid-liquid concentration, fine particle size, and high viscosity. And the rotary vacuum filter

is widely used in sugar industry.

HVD-BFV-P series belt rotary vacuum drum filter is a solid-liquid separation equipment with filter cloth type. In the process of work, under the action of vacuum suction, the material in the tank

passes through the suction pipe into the distribution valve, and then from the outlet pipe of the distribution valve into the back row of the vapor-liquid separator. The solid remains on the filter

cloth to form a filter cake, which is automatically discharged by the discharging roller driven by the traveling filter cloth. The filter cloth enters the cloth washing box through the automatic

rectifying device and is recycled under the double-sided washing of the high-pressure washing water in vacuum drum filter. After the tensioning roller, the filter cloth returns to the surface of

the drum to start the new filtering work.

As rotary vacuum filter manufacturers, we offer the best rotary drum filter price of belt vacuum filter.

Belt Vacuum Filter Features

Rotary vacuum filter manufacturers provides personalized design to meet the needs of different customers;

High production capacity, low wet of filter cake, easy to unload;

Belt vacuum drum filter can achieve continuous automatic operation, simple operation;

The high clarity of filtrate and high recovery rate of materials in rotary vacuum filtration.

Rotary Vacuum Filter Technical Parameter

Pre-coating Vacuum Filter System Technical Parameters

Belt Vacuum Filter Technical Parameters

Rotary Vacuum Filter Working Principle

Vacuum filter is formed in the filtrate outlet negative pressure as the driving force of filtration. This kind of filter is divided into intermittent operation and continuous operation. The vacuum

filter operated intermittently can filter suspensions of various concentrations, while the vacuum filter operated continuously is suitable for filtering thick suspensions containing more solid

particles.

The container is separated into upper and lower cavities by filtering medium, which constitutes a simple filter. The suspension is added into the upper chamber, under the action of pressure through

the filter medium into the lower chamber to become filtrate, solid particles are trapped on the surface of the filter medium to form filtrate residue.

During the filtration process, the filter slag layer accumulated on the surface of the filter medium gradually thickens, and the resistance of the liquid through the filter slag layer increases,

and the filtration speed decreases. When the filter chamber is full of filter residue or the filter speed is too small, stop filtering, remove the filter residue, so that the filter medium

regeneration, to complete a filtration cycle.

Now the price of corn processing plant is affordable, if you have needs, please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2020

- Address: Bldg.202-1207, No.19 Huanjing Road, Tongzhou District, Beijing

- Contact: HongVadar com