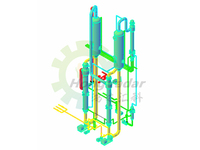

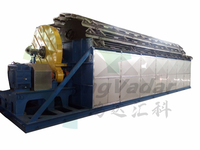

Spray Dryer System

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

HVD-SD-Q a spray dryer works on the principle of drying process in which the raw material solution is separated into droplets in an atomizer and the powder particle shape product is obtained by

direct contact between hot air or other gases and droplets. At present, spray drying technology has been widely used in the production of maltodextrin, detergent, dairy products, dehydrated food,

dye, cement, and fertilizer. The most common milk powder, instant coffee, convenient food soup, and other products are obtained from the spray drying process among and milk spray dryer machine is

really popular.

Features of Spray Dryer System

Fast-drying speed, only a few seconds to complete.

Suitable for drying heat-sensitive materials.

Wide range of use: according to the characteristics of materials, pilot scale spray dryer can be used for hot air drying, centrifugal granulation. Most products with very different characteristics

can be produced with this machine.

Because the drying process is completed in an instant, the particles of the finished product can basically maintain the spherical shape of the droplet, and the product has good dispersibility,

fluidity, and solubility.

Simplified production process and easy operation & control. Spray dryer system is usually used for solutions with a solid content of less than 60%. After drying, there is no need for grinding and

screening, which reduces and simplifies the production process. The particle size, loose density, and moisture of the product can be adjusted by changing operating conditions within a certain

range, which is convenient for control and management.

In order to make the material free from pollution and extend the life of the equipment, all parts in contact with the material are made of stainless steel.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy-saving spray dryer system for the customer. As the

industrial spray dryer manufacturer, the manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels.

Customers can choose international ISO, EU CE, and other standards spray dryer system at a good industrial spray dryer price.

Spray Dryer System Technical Parameter

If you want to know more types of tomato processing plants, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2020

- Address: Bldg.202-1207, No.19 Huanjing Road, Tongzhou District, Beijing

- Contact: HongVadar com