Disk / Flange Forging Component

Specifications

Disk / Flange Forging Component

The basic process used for disk forging is upsetting, and then chamfering, rounding, and leveling as the subsequent auxiliary processes and finishing processes.

The flange is a part that connects the pipe to the valve or other pipes. It is to continuously beat raw material after cutting, so that to eliminate defects such as segregation and looseness in the

steel ingot. The price and mechanical properties are both higher than that of ordinary cast flanges.

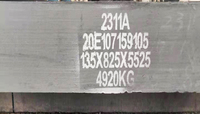

Main Parameters of HS Metal Steel Forged Discs/Forged Flanges For Sale

Forged Disks:Φ70~Φ1200mm

Forged Flanges:Φ70~Φ1200mm

Forged Disk/Flange Common Technical Standards

Round Metal Discs: NB/T47008~47010

Forged Steel Flanges: GB/T3077 EN10083 EN10084 EN10085 JB/T6395

Typical Steel Grades of HS Metal Steel Discs/Forged Flanges For Sale

Forged Discs: #20, #35, 16Mn, 15CrMo, 1.25Cr-0.5Mo, 2.25Cr-1Mo, 2.25Cr-1Mo-0.3V, 12Cr2Mo1V, 21CrMo10, 0-1Cr8Ni9(Ti), 1Cr17Ni2, 304(L), 316L(N), 321, 347, 00Cr19Ni13Mo3, 00Cr22Ni5Mo3N

Forged Flanges: 18CrNiMo7-6, 17CrNiMo6, 20CrNiMo, 20CrNi2Mo, 20CrMnMo, 20CrMnTi, 34CrNiMo6, 30CrNiMo8, 40CrNiMo, 35CrMo, 42CrMo

Custom Forged Discs/Flanges Applications

Like our cylinder forgings products, the forged steel discs for sale can be used for gears, wheels, etc. for port machinery and marine machinery. Pressure vessel forgings for chemical machinery

As one of die steel suppliers, we can offer types of high quality products for customers, anythinf you need, please leave us a message.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai