HOT WORK DIE STEEL

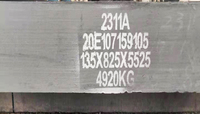

Specifications

As one of the hot die steel manufacturers, we supply high quality hot work die steel to meet the requirements of some customers.

Since hot work steel of die steel products is under high temperature and high pressure conditions for a long time, the hot die steel properties are required to have high strength, hot die steel

hardness and thermal stability, especially high thermal strength, thermal fatigue, toughness and wear resistance.

HS DVN/ HS DVN-Nb Hot Work Die Steel

HS DVN / HS DVN-Nb steel has high high-temperature strength and thermal fatigue resistance, is widely used in casting dies.

HS S350 Hot Work Die Steel

The special composition of HS S350 steel makes it have high high-temperature strength and thermal fatigue resistance.

HS PH13 Hot Work Die Steel

HS PH13 optimizes the alloy element ratio on the basis of traditional H13, and reduces the content of harmful elements.

HS H13-MOD Hot Work Die Steel

HS H13-Mod is modified improved high-thermal-strength hot work tool steels, optimizing the ratio of C and Cr alloy elements on the basis of traditional H13, reduces the content of harmful elements.

HS PH11 Hot Work Die Steel

HS PH11 Hot Work Die Steel is modified high-toughness, high-isotropy, high-quality hot work & plastic mold steel with good cold and hot fatigue resistance and corrosion resistance.

HS 2343ESR-S Hot Work Die Steel

As large-size (thickness range 400-750mm) and high-polished plastic mold steel. It has high purity and good structure uniformity through unique smelting and heat treatment process.

HS CR7 Hot Work Die Steel

Under the conditions of high hardness (≥55HRC), HS CR7 still has good red hardness and abrasion resistance, as well as good toughness.

HS 2344 Hot Work Die Steel

HS 2344 is pressure-resistant hot-working die steel whose performance and use are basically the same as that of H13 steel, and it is one of the widely used hot work die steels.

HS 2714 Hot Work Die Steel

HS 2714 is chromium-nickel-molybdenum-vanadium alloy steel with good hardenability, toughness, and thermal resistance. After quenching and tempering, the steel has good overall performance.

FAQs of Hot Work Die Steel

What is hot work die steel?

Hot-work die steel refers to alloy tool steel suitable for making molds for thermal deformation processing of metals, such as hot forging dies, hot extrusion dies, die-casting dies and hot

upsetting dies. there are many types such as 4cr5mosiv1, 3cr2w8v and 5crnimo.

What material is suitable for hot-cutting die steel?

The mold steel material has to withstand a lot of impact when working and still maintain high mechanical properties when in contact with high temperatures, so it needs to have high strength,

toughness and wear resistance, as well as high tempering stability and thermal fatigue performance. Alloy die steel can meet the requirements, and be used to manufacture thermally deformed dies

such as hot forging dies, flashing dies and hot cutting dies.

What is H13 tool steel?

H13 material is a Hot work tools steel with 5% chromium. Its high impact strength protects against cleavage cracking and is easy to machine. This steel is designed to retain hardness at elevated

temperatures and withstand the effects of alternate heating cooling. In China, the corresponding steel grade to it is 4Cr5MoSiV1.

Want to know more details of hot work steel, contact us.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai