Air Dryer System

Specifications

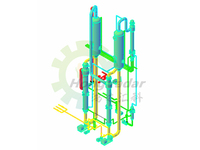

HVD-AD-P series air dryer dehydrator working system unit is composed of an air heater, air filter, disintegrating disc, thrower, venturi pipe, air drying pipe, cyclone separator, induced draft fan,

and other equipment. The rapid movement of the heat-carrying airflow is used to suspend the dried material, and the change of the pulse tube with different diameter and airflow velocity is used to

make the material keep rolling, strengthen the drying process and improve the heat transfer coefficient, so as to achieve the purpose of drying. The drying time is only about 3~5 minutes, and the

temperature of the material to be dried should not exceed 60 degrees.

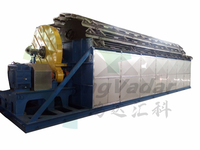

HVD-AD-P series air dryer dehydrator working system can be widely used in powder, flake, heat-sensitive materials drying. Especially suitable for corn, potato, and other raw materials to produce

starch, protein powder drying, and food, chemical, pharmaceutical, medical, agricultural, and sideline products and other granular loose materials drying.

Main Feature Of Air Dryer System

High heat transfer coefficient, can continuously dry a large number of materials;

Fast-drying speed, good material quality;

Working under negative pressure, clean working environment and pollution-free;

Low consumption;

Easy operation, small area needed, and low investment.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy-saving instrument air dryer system and industrial air dryer

in pneumatic system for the customer. As a air dryer company, we make differnent sandblasting air dryer for sale. Large or small air dryer, warm or hot industrial air dryer, compact air dryer, air

flash dryer etc. The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can

choose international ISO, American AWS, European EN, and other standards for equipment design and production according to their needs.

Air Dryer System Technical Parameters

Model Commercial starch output, T/H Feed water content, % Discharge moisture content, % Steam consumption

kg steam / kg water Power

kW

HVD-AD1.0-P7.5 1.0 <40 12-14 1.8-2 7.5

HVD-AD2.0-P11 2.0 <40 12-14 1.8-2 11

HVD-AD3.0-P22 3.0 <40 12-14 1.8-2 22

HVD-AD4.0-P37 4.0 <40 12-14 1.8-2 37

HVD-AD6.0-P90 6.0 <40 12-14 1.8-2 90

HVD-AD10.0-P110 10.0 <40 12-14 1.8-2 110

HVD-AD15.0-P132 15.0 <40 12-14 1.8-2 132

HVD-AD20.0-P132 20.0 <40 12-14 1.8-2 132

For more starch processing plant products wholesale at competitive price directly from China factory.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2020

- Address: Bldg.202-1207, No.19 Huanjing Road, Tongzhou District, Beijing

- Contact: HongVadar com