HS H13-MOD Hot Work Die Steel

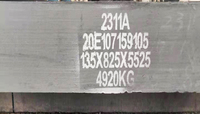

Specifications

As modified improved high-thermal-strength hot-work die steel, HS H13-Mod of h13 equivalent material , optimizes the ratio of C and Cr alloy elements on the basis of traditional H13, reduces the

content of harmful elements such as P and S, so that h13 steel equivalent has good thermal stability and thermal fatigue resistance.

Chemical properties of HS H13-MOD

Steel Grade C Si Mn P S Cr Mo V

HS H13-Mod 0.30~0.40 1.20~1.60 0.30~0.50 ≤0.015 ≤0.003 3.50~4.50 0.80~1.20 0.80~1.00

Features of HS H13-MOD

High resistance of tempering softening properties (the using temperature can improve 50℃ comparing with H13 steel).

Excellent Thermal Stability: the moulding die manufacturing of the H12-MOD can be under long time preservation of 620℃, the hardness is always higher than that of H13 esr, and still maintain above

35HRC.

High thermal fatigue resistance: better than that of H13 steel.

Performance curve of tempering and CCT curve (continuous cooling transformation).

Recommend Heat Treatment of HS H13-MOD

Heating Temperature/℃ Cooling Way Hardness (HRC) Tempering Temperature/℃ Tempering Numbers Hardness (HRC)

First Preheating Second Preheating Last Heating

500~600 820~860 1010~1060 Oil Cooling 53~55 560~600 2~3 47~50

As one of die steel suppliers, we can offer sorts of related products for sale, anything you need, please contact us.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai