HS PH11 Hot Work Die Steel

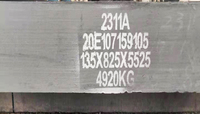

Specifications

As modified high-toughness, high-isotropy, high-quality hot work & plastic mould steel, the steel has good cold and hot fatigue resistance and corrosion resistance, good cold and hot workability,

good hardenability, and high thermal strength and oxidation resistance performance at medium temperature, as well as high toughness and wear resistance.

Chemical properties of HS PH11

Steel Grade C Si Mn P S Cr Mo V

HS PH11 0.35-0.40 1.00-1.20 0.30-0.50 ≤0.010 ≤0.020 5.00-5.20 1.20-1.50 0.40-0.60

Application of HS PH11

Die-casting mold (mold core, insert, sprue spreader, nitrided ejector pins);

High-strength plastic mold by injection molding;

Extrusion mold (mold core, mold pad, choke block);

Hot press forming dies for aluminum, copper and magnesium;

Cold punch, hot shear, shrink ring and wear-resistant parts.

Features of HS PH11

With electroslag remelting, high-temperature diffusion annealing and ultra-fine heat treatment, the uniformity of the structure is good, and the carbides are finely dispersed;

Good heat and cold fatigue resistance and corrosion resistance, good cold and hot workability, high die hardness and wear resistance;

High purity control brings high polishability;

High isotropy, aspect ratio ≥0.85;

Annealing hardness ≤200HB, quenching hardness 50-60HRC, tempering hardness 46-48HRC.

If you want to know more about h11 steel equivalent, please contact us.

As one of die steel manufacturers, we will do our best to meet all the needs of customers.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai