HS 2738 Plastic Die Steel

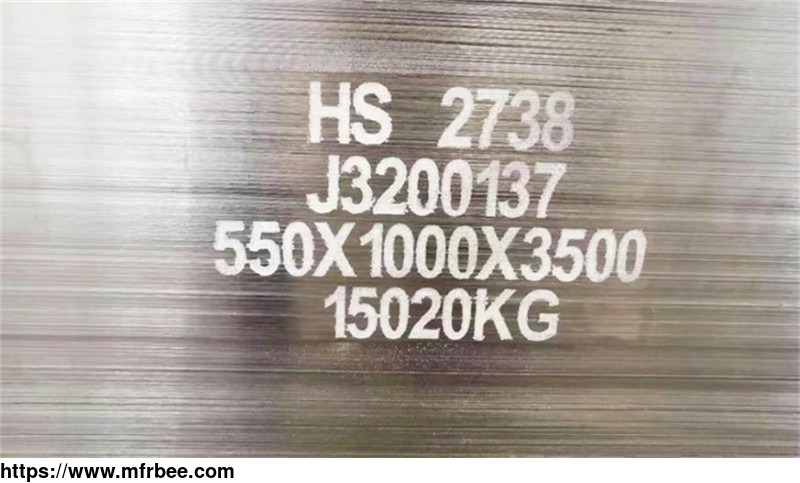

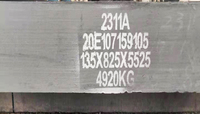

Specifications

HS 2738 steel is modified pre-hardened mirror plastic mold steel. Key technologies of alloy composition optimization and organization control ensure that the module has high hardness uniformity,

excellent polishing performance and processing performance at the largest cross-sectional size. It is a new generation of super-large cross-section pre-hardened plastic mold steel.

Chemical properties of HS 2738

Steel Grade C Si Mn P S Cr Ni Mo

HS 2738 0.30~0.40 0.20~0.50 1.00~1.50 ≤0.010 ≤0.030 1.50~2.00 0.80~1.20 0.25~0.40

Application of HS 2738

Plastic molds of compression and injection.

Dies of Car bumpers, dashboards, TV cabinets, washing machine drums, etc.

Features of HS 2738

Good welding performance of hardened modules.

Good polishing property of plastic mold steel (high hardness uniformity, section hardness fluctuation ≤ 3HRC).

Excellent processing performance.

Max. thickness reaches 1200mm and the finished module weighs 35MT.

Application hardness: 32~38HRC.

If you want to know more about 1.2738 steel equivalent, please visit our website.

As one of die steel manufacturers, we can offer sorts of die forgings for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai