HS A4 Cold Work Die Steel

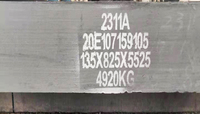

Specifications

As modified cold work tool steel, HS A4 is improved high-toughness impact-resistant cold work die steel. It has fine and uniform ledeburite carbides, high toughness and impact resistance, and is

not easy to crack when used for molds with complex shapes. The steel is a new generation of high-strength, high-impact cold-work die steel.

Chemical Properties of HS A4 Material Equivalent

Steel Grade C Si Mn Cr Mo V Ni

HS A4 0.65~0.90 0.70~1.00 0.70~1.10 2.20~3.50 0.20~0.50 0.15~0.35 0.30~0.60

Application of HS A4

Cold stamping dies (home appliance punching die, gasket punching die, all kinds of connecting rod reed die, etc.), cold extruding dies (clutch, gear, flange plate and guide tube etc.), cold heading

dies (cavity and punch pin, etc.), cold shear blade for plate.

Features of HS A4

Heat treatment hardness of this kind of cold work die steel is equivalent as that of D2 steel, and the toughness is more than 3 times of that of D2, while the wear-resistance is slightly lower than

that of D2 steel.

Long service life under high stress impact

Cutting processing performance is better than that of D2 steel

Deformation of heat treatment

Performance curve of quenching and tempering

Recommend Heat Treatment of HS A4

QUENCHING TEMPERING

Heating Temperature/℃ Cooling Way Hardness (HRC) Tempering Temperature /℃ Tempering Numbers Hardness (HRC)

Preheating Last Heating

500~600 850~950 Oil Cooling 60~65 160~200 2 60~63

If you are looking for a reliable die steel supplier, please contact us, and we will be your best partner.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai