HS DC53 Cold Work Die Steel

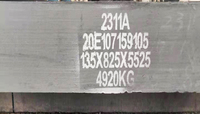

Specifications

Oue company strive to supply high quality of cold work die steel, and the HS DC53 is an important one.

As high-toughness high-wear-resistance cold work die steel, HS DC53 equivalent, can be applied to stamping dies and cold forging dies, which is dc53 steel equivalent, 1.2990 steel, sld-magic and

assab 88.

DC53 Steel Chemical Properties

DC 53 Steel Applications

Our DC53 steel and DC53 equivalent material can be used to conduct precision stamping dies, cold forging, deep drawing, and thread rolling die, auto parts bending dies, bicycle parts dies,

hydraulic forming dies, high-speed blanking punches, stainless steel plate punches, etc.

DC53 Steel Features

The DC53 steel and its equivalent material has high toughness, high wear resistance, and good high-temperature anti-tempering stability, and has a small risk of chipping or cracking during use.

DC 53 Steel Heat Treatment

QUENCHING TEMPERING

Prog-ram Heating Temperature/℃ Cooling Way Hardness(HRC) Tempering Temperature /℃ Tempering Numbers Hardness(HRC)

First Preheating Second Preheating Last Heating

Ⅰ 500~600 820~860 1010~1060 Oil Cooling 60~65 170~230 2 61~63

Ⅱ 500~600 820~860 1010~1060 Oil Cooling 60~65 510~540 2 60~62

DC53 Steel Equivalent Material

DC53 special steel and its equivalent material are a new type of cold work die steel from Japan Daido steel, improved on SKD11. The heat treatment hardness of the DC53 steel is higher than SKD11,

reaches 62-63HRC after tempering at 520-530℃. DC53 exceeds SKD11 in strength and wear resistance, and the toughness is twice that of SKD11, which is more prominent in cold work die steel. The tools

made of DC53 rarely have cracks, which greatly improves the service life.

You can find DC53 steel equivalent to ASSAB 88 / Cr8Mo1VSi from GB/T standard / modified A8 from FINKL / SLD8 from HITACHI / K340 from BOHLER

If you are looking for a reliable die steel suppliers, please contact us, and we will be your best partner.

Now the price of forged bars is reasonable, if you have needs, please contact us.

- Country: China (Mainland)

- Address: No.1 Dongmeng Rd,Dongmeng Technology Industrial Aggregation Area, Guanshan Village,Nanzha Street, Jiangyin,Jiangsu,China

- Contact: Echo Dai