Casing Head

Product Quick Detail

- FOB Price

- USD $200,000.00 / Piece

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 45days

Specifications

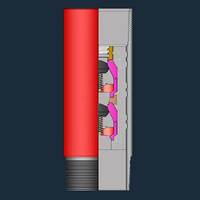

Casing head is a kind of new product which is designed according to customers' requirements and applied in all deep wells and completion operation. lt is mainly used to fix wellhead connect casing

string and seal, and control the pressure of casing annular space. The casing head assembly consists of the casing head, valve spool, casing hanger and bypass valve.

wellhead casing head is made of low-alloy steel with good loading capacity and H2S penonnance. The connection type is divided into welded types: threaded type and slip type. The casing hanger is

equipped with cons-shape sealing mechanism and BT sealing mechanism. Its sealing mechanism is superior under the force of gravity, which can be used more conveniently 2nd quickly in the field. Its

structures can be divided into mandrel and slip types.

Features of Casing Head:

1.The casing is hung with a rigid and rubber composite sealing structure, and a metal seal can also be used to reinforce the sealing performance of the product;

2.Designed with anti-wear sleeve and pressure test removal tool to facilitate the removal of the anti-wear sleeve and the pressure test of the casing head;

3.Casing head flank valve configuration, designed according to user requirements

Application of Casing Head:

The casing head is installed at the upper end of the surface casing string, and is used for suspending the casing of the casing other than the surface casing and the wellhead device component of

the annular space of the sealing casing. The main functions are as follows:

1. Hanging part or all of the weight of each layer of the casing other than the surface casing by the hanger;

2. Connect a wellhead device such as a blowout preventer;

3. Forming a pressure seal between the inner and outer casing strings;

4. Providing an outlet for releasing pressure that may accumulate between the two casing strings;

5. In an emergency, the fluid can be pumped into the well from the side hole of the casing head, such as killing fluid or fire extinguishing agent;

6.Special operation: a. The cementing quality is not good. The side hole can be filled with cement. b. When acidizing and fracturing, the pressure balance liquid can be injected from the side hole.

Technology Parameters of Casing Head:

Casing Program 20 〞 X13 3/8 〞 X9 5/8 〞 X 7 〞or 5 1/2 〞

Side Outlet Connection PFF35/80 ring gaskets :R35

PFF70/65 ring gaskets :BX153

Load Bearing ≤ 5000KN

Hanger Type 4 〞、 5 〞、 4 1/2 〞、 5 1/2 〞、 7 〞

Working Pressure 35Mpa~70Mpa

Performance Requirement Level PR1

Product Specification Level PSL1-3

Temperature Class P·U (-29℃~121℃)

Material Class AA~FF

SAIGAO GROUP, as an excellent oil equipment suppliers, offers a wide range of oilfield cementing tools for you to choose from.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2008

- Address:Zhongrun Century Center, No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

- Contact:Rex Liu

Other products from Shandong Saigao Group Corporation

Relate products of Casing Head

Solid CBN Inserts for Head Turning Cast Iron and Hardened steels

关键词: 描述: 细节 整体 CBN 刀片规格 型号:SNGN、SCGN、CNGN、TNGN、DNGN、RNGN、RCGX、RCGV等 整体CBN刀片的应用:刹车盘、刹车鼓、泵零件、齿轮、阀门、轴承、滚子、发动机气缸盖、气缸套、气缸体、动力等。 ...

Diamond Honing Stone, Honing Stick, Honing head

细节 珩磨石的介绍 原则上,完美的磨刀石由三种不同的主要成分组成,可提供所需的切割效果。 磨料 磨料是每块珩磨石最重要的组成部分。使用各种粒度的合成金刚石或立方氮化硼 (CBN)。 纽带 ...

Waterproof EVA Carrying Case for Electronic, Custom Hard Shell Storage Case With handle For Travel

Custom EVA Case Specifications Material: Outer Shell: Ethylene-Vinyl Acetate (EVA) Inner Lining: Soft Fabric (e.g., Velvet, Lycra, or Nylon) Zippers: Heavy-duty, rust-resistant metal zippers Handles: Ergonomic, load-bearing handle (optional: detachable shoulder strap) Custom ...