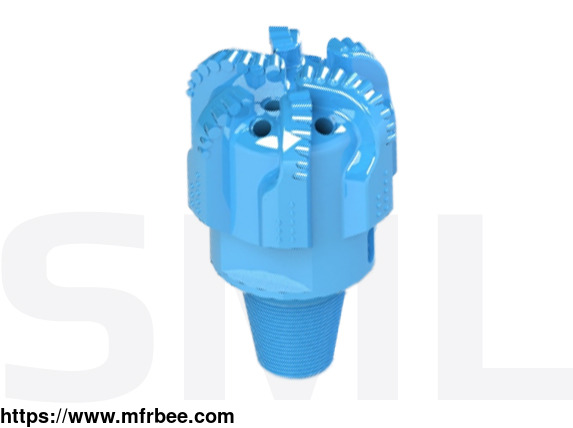

STEEL PDC BIT

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

The drill body of the Steel PDC Bit is made of a whole piece of alloy steel by machining, and the cutting teeth are made by welding the composite piece on the tungsten carbide material tooth post,

and then the cutting teeth are inlaid on the drill body, and the diameter-preserving part is also inlaid with diamond blocks or other wear-resistant materials on the drill body.

Steel PDC bit is suitable for fast drilling in the stratum which is easy to drill at the bottom of the compressive strength without gravel, and it has a wide flow channel also in the timely

transportation of rock brow.

Different Types Of Steel PDC Bit For Sale

Steel PDC Drill Bit

Steel PDC bits are mainly used in difficult to drill formations with high gravel and compressive strength.

Features Of Steel PDC Bit

The Steel PDC bit is a one-piece bit, and the bit parts should not fall off during drilling, so it can be used at higher speed and can withstand greater lateral load without downhole accidents.

The Steel Body PDC bit mainly relies on the cutting action of the PDC composite piece to break the rock, similar to the cutting principle of the scraper bit, with low torque and good stability

during drilling, and high mechanical drilling speed under smaller drilling pressure and high rotational speed.

Steel PDC bits are wear-resistant and long-lasting when used correctly, and are suitable for deep wells and abrasive formations.

Advantages Of Steel Body Over Matrix Body PDC Bits

The entire body of the Steel PDC Bit is made of medium carbon steel and machined.The PDC cutting teeth are fixed to the crown of the drill by means of a pressure fit. The crown of the bit is

surface hardened (sprayed with tungsten carbide wear layer, carburized, etc.) to increase its resistance to erosion. The main advantage of this type of drill bit is the simplicity of the

manufacturing process. Steel Body Bits have a larger chip flute area, higher flank height and narrower flank thickness than tire body bits.

SML produces Steel Body PDC bits with tungsten carbide dressing wear layer, which enhances the wear resistance and erosion resistance of the steel body PDC bit flanks; improves the hydraulic

performance for drilling in soft strata, resulting in better chip evacuation; enhances the protection of cutting teeth; improves the reliability and erosion resistance of the bit; and combines the

advantages of tire body bits and steel bits to increase the mechanical drilling speed.

- Country: China (Mainland)

- Founded Year: 2014

- Address: No. 009-12F, D2 Software New TownHuacheng Avenue, East Lake Development ZoneWuhan

- Contact: smlpdcbit com