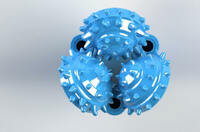

TCI Tricone Bit

Specifications

Under the effect of the WOB and the twist of the drill string, the teeth of the tci tricone drill bits are crushed and eaten into the rock, and at the same time there is a corresponding sliding to

shear the rock. When it rolls at the bottom of the well, the teeth on it will impact and press into the formation in sequence. This effect can crush a part of the rock at the bottom of the well,

and at the same time rely on its sliding to weaken the shearing effect of the teeth. The remaining rocks in between break all the rocks at the bottom of the well and allow the wellbore to be

extended. Explore our wide range of tci drill bit for sale, each designed for optimal drilling efficiency and durability.

TCI Tricone Bit Performance

The roller cone bit has the functions of impacting, crushing and shearing the formation rock when it rotates, so the roller cone bit can adapt to various soft, medium and hard formations.

The 8 1/2'' inch IADC437 roller cone bit is suitable for low compressive strength and high drillability of large sections of very soft ground, such as shale, clay, sandstone, conglomerate, etc.

Our TCI bit is engineered for exceptional performance in challenging drilling conditions, offering enhanced durability and drilling speed.

As a professional drill bit suppliers, SML has high-quality pdc bit, Welcome to contact us if needed.

- Country: China (Mainland)

- Founded Year: 2014

- Address: No. 009-12F, D2 Software New TownHuacheng Avenue, East Lake Development ZoneWuhan

- Contact: smlpdcbit com