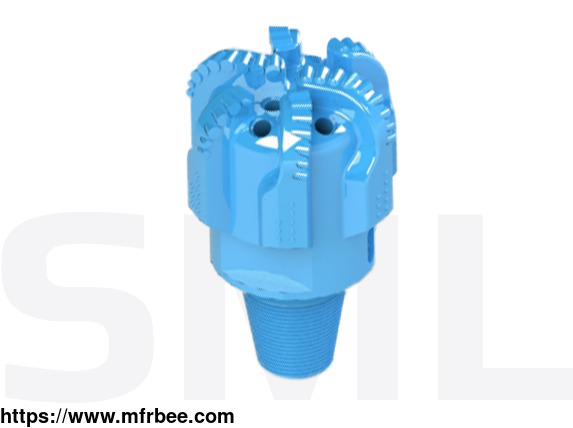

STEEL PDC BIT

Specifications

The drill body of the steel body pdc bit is made of a whole piece of alloy steel by machining, and the cutting teeth are made by welding the composite piece on the tungsten carbide material tooth

post, and then the cutting teeth are inlaid on the drill body, and the diameter-preserving part is also inlaid with diamond blocks or other wear-resistant materials on the drill body.

Steel PDC bit is suitable for fast drilling in the stratum which is easy to drill at the bottom of the compressive strength without gravel, and it has a wide flow channel also in the timely

transportation of rock brow. Click to learn more about PDC drill bits manufacturers.

Features Of Steel PDC Bit

Design: The Steel PDC bit is a one-piece design, ensuring stability at higher drilling speeds and resistance to lateral loads.

Performance: Utilizing the PDC composite's cutting action, it achieves low torque, excellent stability, and high drilling speeds, especially under minimal pressure.

Durability & Application: Steel PDC bits are wear-resistant, ideal for abrasive formations and deep-well operations.

Advantages Of Steel Body Over Matrix Body PDC Bits

Composition: The Steel PDC Bit by Top Tool is meticulously crafted from medium carbon steel, with its cutting teeth pressure-fitted onto the crown. Surface treatments like tungsten carbide spray

heighten its erosion resistance.

Features: Distinctively, Steel Body Bits have an expansive chip flute area, elevated flank height, and a slimmer flank thickness, positioning them ahead of tire body bits.

Top Tool's Advanced Design: Top Tool's PDC drill bits are enhanced with a tungsten carbide layer, amplifying wear resistance and optimizing hydraulic performance, especially in soft strata. This

design amalgamates the advantages of various bits, ensuring superior drilling speed.

There are many pdc bit manufacturers, but we are one of the best choices for you.

- Country: China (Mainland)

- Founded Year: 2014

- Address: No. 009-12F, D2 Software New TownHuacheng Avenue, East Lake Development ZoneWuhan

- Contact: smlpdcbit com