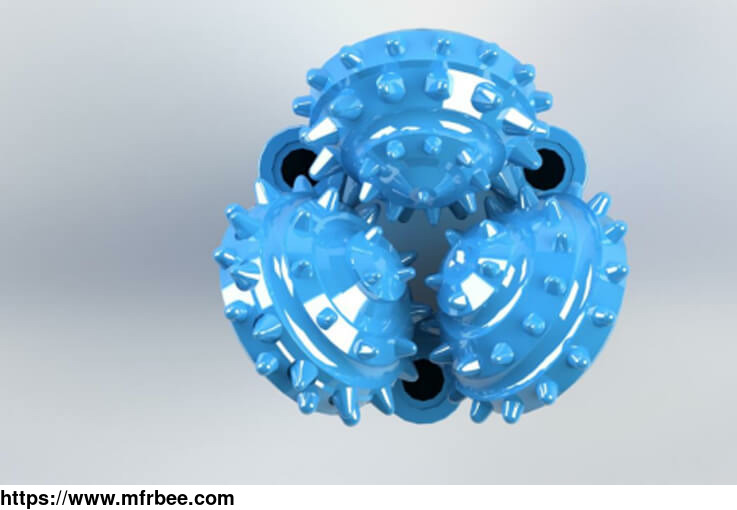

STEEL TOOTH BIT

Specifications

The Steel Tooth Bit teeth are crafted from milled tooth wheel blanks, primarily featuring wedge-type designs. A balanced tooth structure promotes rock breaking and tooth strength. Soft strata typically have larger tooth height, width, and spacing, whereas hard strata exhibit the opposite. To enhance wear resistance, the teeth\'s working surface is coated with carbide, while a carbide layer on the back vertebrae ensures diameter preservation.

What Strata Are Steel Tooth Bit Suitable For?

IADC517: Low compressive strength, high drillability soft strata, such as shale, clay, sandstone, soft limestone, etc;

IADC537: low compressive strength, medium soft, with hard abrasive interbeds, such as hard shale, hard gypsum, soft limestone, sandstone, dolomite with interbeds, etc.;

IADC617: high compressive strength, medium hard, with thick hard interlayer, such as hard shale, limestone, sandstone, dolomite, etc.;

IADC637: High compressive strength, medium hard and highly abrasive strata, such as limestone, dolomite, sandstone flint, etc;

The Difference Between Steel Tooth Bit And TCI Bit

TCI Bits:

Compositions: Constructed with high-strength, high-toughness carbide teeth.

Design: An optimized configuration maximizes wear resistance and cutting capability.

Application: Ideal for hard and abrasive formations such as tunnel stone and quartzite.

Usage: Predominantly used in oil drilling due to its versatility across formations.

Steel Tooth Bits:

Compositions: Teeth are directly milled onto the tooth wheel blank.

Design: Enhanced with a tungsten carbide layer for increased wear resistance and self-sharpening attributes.

Application: Best suited for softer, less abrasive terrains.

Usage: While they excel in softer terrains, they also retain high mechanical drilling speed.

As a professional drill bit suppliers, SML has high-quality pdc drill bit. Welcome to contact us if needed.

- Country: China (Mainland)

- Founded Year: 2014

- Address: No. 009-12F, D2 Software New TownHuacheng Avenue, East Lake Development ZoneWuhan

- Contact: smlpdcbit com