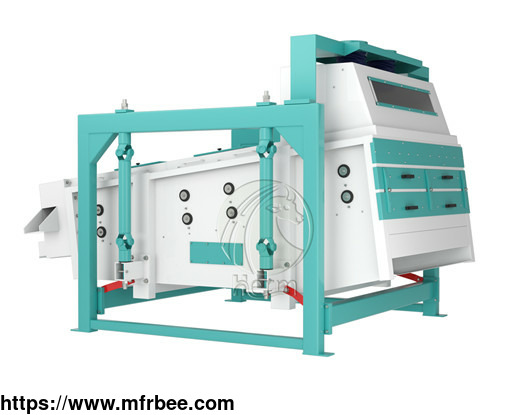

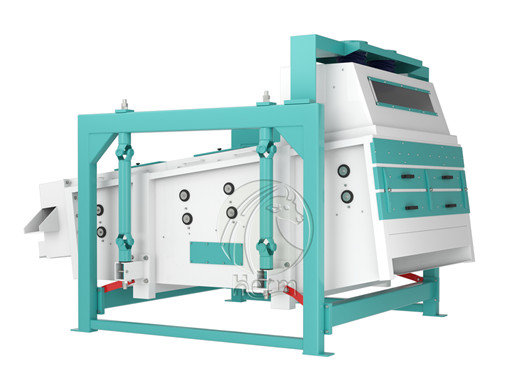

Cleaner and Separator

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 45 Days

Specifications

HZXZ Grain Cleaner and Separator Introduction

The rotary vibrating screen is mainly used for the initial cleaning of large outputs of grains before entering the warehouse, the cleaning of drying feed, and the processing and cleaning of the pipeline of the feed processing workshop.

It is widely used in feed, food, chemical, wine, and other industries. It has high overall strength, large output, good cleaning and grading effect, universal joint hanger, strong and durable, with feeding uniform material device, metal screen lattice easy to load and unload, bearing free. It works better with the wind separator.

HZXZ Grain Cleaner and Separator Features

1. Suitable for cleaning large and small materials of large output, widely used in food, chemical, wine, and other industries

2. High overall strength, large output, good cleaning, and grading effect

3. Universal joint boom, strong and durable

4. With feed homogenizer

5. Easy loading and unloading of metal screen

6. Combined material line realizes circular, elliptical, and linear motion, providing production efficiency

7. Visual observation port to observe production situations in real-time

8. Laser cutting ensures the quality and precision of sheet metal parts

9. Carbon dioxide gas-shielded welding process

10. The bouncing ball moves without a dead angle, eliminating all possible blocking

HZXZ Grain Cleaner and Separator Applications

1. This machine together with the aspiration channel or recycling aspiration system is widely applied in feed mills and silos storage cleaning sections.

2. It is also successfully used in feed mills, seeds cleaning plants, oilseed cleaning plants, cocoa bean and cocoa nib grading systems in chocolate factories, and other plants.

3. Food processing and feed manufacturing industries. The pure material flows directly into the net material outlet along the lower surface of the sieve.

- Country: China (Mainland)

- Business Type: Henan Herm Machinery Co., Ltd.,Manufacturer

- Market: Africa,Middle East

- Founded Year: 2010

- Address: No.50 Futing Road, Fugou Industrial Park,Fugou County

- Contact: Merry Zhang