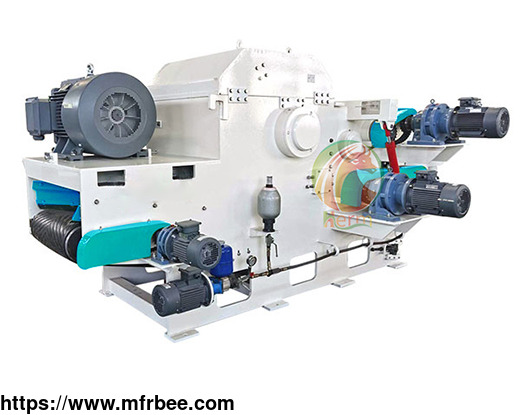

Drum Wood Chipper Shredder

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 45 Days

Specifications

Drum Wood Chipper Shredder Introduction

Our drum wood chippers are specialized equipment for the production of wood chips. Widely used in particleboard factories, medium and high-density fiberboard factories, straw factories, biological power plants, wood chip factories, and other industries. Drum wood chippers have a large infeed, and logs or bales of wood with a diameter of more than one meter can be processed reliably in larger wood chippers. The main raw materials for cutting are small-diameter timber, timber harvesting, and processing residues (such as branches, plates, skins, log cores, waste veneers, etc.), and can also be used for cutting non-wood raw materials (such as sugarcane, reed, bamboo, etc).

Drum Wood Chipper Shredder Advantages

1. Customizable Design: The size and model can be customized according to the customer's end-use and production capacity.

2. Flexible Operation: Upper feeding roller assembly can float up and down within the prescribed scope under the effect of hydraulic, to achieve the function of cutting raw materials with different thicknesses.

3. Reasonable Design: Materials after cutting will discharge through screen holes, those that don't meet the requirement will be cut again in the machine until they reach the standard.

4. Long Service Life: The use of heavy-duty self-centering bearings, even if the equipment is in continuous operation at full load, also has a long service life.

5. Secondary Refinement: The chipping machine is equipped with a crushing screen to realize the secondary refinement of oversized woodblocks.

6. Wide Application: It can be widely used in particleboard factories, medium, and high-density fiberboard factories, furniture factories, biomass power plants, wood chip factories, and biomass preparation industries in the biomass energy industry.

Drum Wood Chipper Shredder Working Principle

The drum-type wood chipper is composed of the body, knife roller, upper and lower feed rollers, conveyor belt, hydraulic system, and so on. The machine body is welded with high-strength steel plates, which are the supporting basis of the whole machine. Two or three or four flying knives are installed on the knife roll, and the flying knives are fixed on the knife roll by professional flying knife bolts through pressing blocks. According to the thickness of the material to be cut, the upper feeding roller assembly can float up and down within a certain range through the hydraulic system. The cut pieces that are qualified fall through the sieve holes and are discharged from the bottom. Large pieces will be cut in the machine.

- Country: China (Mainland)

- Business Type: Henan Herm Machinery Co., Ltd.,Manufacturer

- Market: Africa,Middle East

- Founded Year: 2010

- Address: No.50 Futing Road, Fugou Industrial Park,Fugou County

- Contact: Merry Zhang