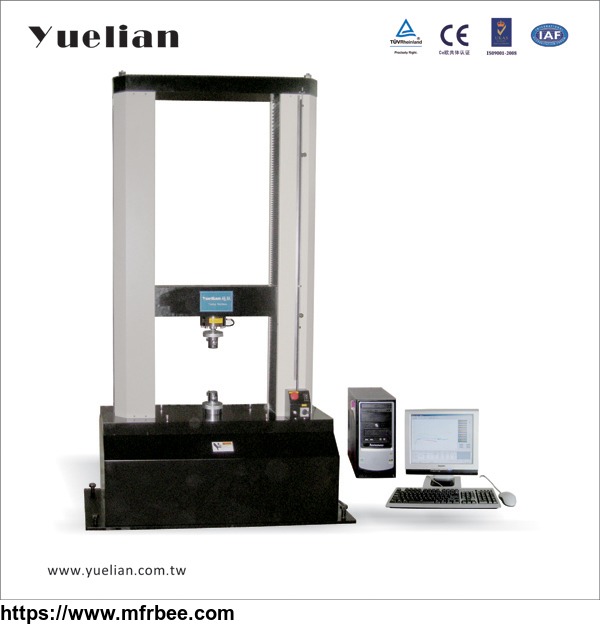

YL-1151 Plastic Tensile Testing Machine

Product Quick Detail

- FOB Price

- USD $7,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China(Mainland)

- Force Resolution

- 1/500,000

- Test Stroke

- 1000mm

- Test Width

- 550mm

- Test Speed

- 0.001~1000mm/min

- Power

- 1500w

- Packaging

- 1 set each plywood case

- Delivery

- 30 Days

Specifications

Feature

Rigid frame structure is not easy to be deformed. Precise servo motor and such as ball screw driving parts supply with stable test speed. Strong and functional computer system provides a complete test function; assemble with different grips/accessories are able to do various material test.

Standard

ISO 7500-1 , JJG475-88 , ASTM E4 , DIN5122 , JIS B7721/B7733 , EN 10002-1,EN 1002-2, BS1610,GB T228

Specification

| Capacity: | 1KN, 2KN, 5KN, 10KN, 20KN, 50KN, 100KN (Available for double capacities) |

| Display | Computer display |

| Force Resolution | 1/500,000 |

| Force Accuracy | ≤±0.3% |

| Stroke Resolution | 1/500,000 |

| Control Mode | Full computer operating mode |

| Test Stroke: | 1000mm |

| Distance between two columns(Test Width): | 550mm |

| Test speed: | 0.001~1000mm/min Computer set with up and down quick adjustment button of grips |

| Stop Mode: | Overload stop, emergency stop, specimen damage automatic stop, upper and lower limit automatic stop, automatic reset function |

| Machine Drive: | Servo-motor driven, synchronous wheel and precision ball screw drive |

| Force sensor: | Load Cell comply with ASTM-E4 standard which accuracy is limited within 1.0 % |

| Dimension: | 92*75*199cm (W*D*H) |

| Weight: | About 1150kg |

| Power: | 1500W |

| Voltage: | 220V 50/60HZ 10A |

| Accessories | 1 set of grips, test software, USB computer connection wire |

| Optional: | Personal computer |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 1994

- Address: No.1115,Building A,Tianan Digital City,Huangjin Road,Baima,Nancheng

- Contact: David Mo