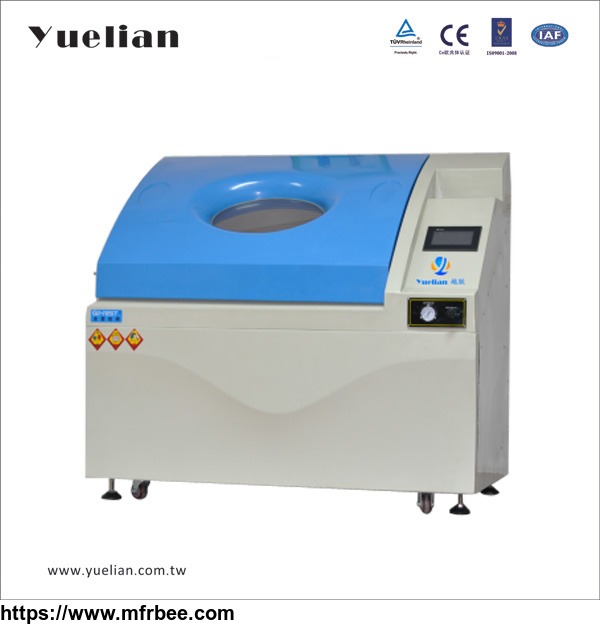

SAC Compound Salt Spray Chamber

Product Quick Detail

- FOB Price

- USD $4,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China(Mainland)

- Temperature Range

- -40~80℃

- Air Compression

- 40~120 psi

- Temperature Range

- RT~60℃

- Packaging

- 1 set each plywood case

- Delivery

- 30 Days

Specifications

Product Description

SAC compound salt spray chamber (selecting functions as per testing requirement, such as salt smog, dry, low temperature, humidity, condensation, immersion) simulates and combines the most common natural environment conditions, testing product damage extent in certain period of time. The test chamber, with permutation and combination(of salt smog, dry air, standard atmospheric pressure, constant temperature & humidity, low temperature, etc..), several times harsher conditions than natural environment, carries out combined cycle tests, even in arbitrary sequence. China formulates relevant national standards for salt spray testing with detailed explanations, and develops salt spray testing from initial simple neutral salt spray test to acetic acid salt spray test, copper salt accelerated acetic acid salt spray test and cyclic salt fog test forms. This tester, using touch screen automatic method, to simulate precise testing environment conditions, is a rare one in the domestic market with such ultra high performance price ratio.

Application

The tester is widely used in aerospace, automotive, motorcycle, soldiers loaded weapons, electronics, chemical coating, quality measurement, ship/railway enterprises and institutions/colleges/scientific research units. It is one of those important and essential equipment for testing environmental adaptability and reliability of protective layer of metal materials, a variety of components, electronic components and industrial products

Standards

ASTM-B117,B287,B-380,JISD-0201,H-8610,H-8502,Z-2371,K-5400,DIN50021-75,ISO3768/3769/3770,GJB150,CNS3627/3885/4159/7669/8866,B/T2423.17,B/T10125-1997

Product Structure Characteristics

1.Comprehensive anti-corrosion structure; High performance strengthened type multilayer glass fiber polyester resin case; Variety of accessories and auxiliary facilities(made of high temperature resistant and corrosion resistant materials, with reinforced steel frame). Good tolerance to chemical products and high temperature corrosion resistance, and no electrochemical corrosion reaction occurred.

2.Touch screen programmable controller; Complete display of test data; Chinese and English switching.

3.Spray, dry and wet humid cycles can be completely controlled.

4.Salt spray generated smoothly by a special precision nozzle, ensuring the uniform distribution of salt spray and the collection rate of the chamber.

5.Mobile external salt solution tank, flow meter to accurately monitor the salt solution flow.

6.The chamber lid is opened for pneumatic on/off(optional), equipped with adjustable casters and a base, free and relaxed.

7.With automatic mist removal device, test sample can be clearly observed after testing.

8.Salt spray test chamber has multiple system protections, is safe and reliable. All electrical appliances are equipped with circuit breakers; All industrial heaters are equipped with electronic and mechanical overheating protection device.

9.The air conditioning device and the pressure gauge can monitor the air pressure, requirement for precise spray distribution.

SAC Compound Corrosion Test Chamber, Specifications / GRP mould forming

| Model | SAC-420 | SAC-1008 | SAC-1512 |

| Interior Dimension (L*W*H)mm | 1000x700x600 | 1600x900x700 | 2100x900x800 |

| Exterior Dimension (L*W*H)mm | 1560x1000x1350 | 2160x1200x1450 | 2710x1150x1570 |

| Temperature Range | -40~80℃ | ||

| Test Solution | Pure Water + Sodium chloride(as per Standard) | ||

| Power | 220V 50/60HZ single phase, other voltage power supply can be required to provide | ||

| Air Compression | 40~120 psi(customer self-owned air compressor) |

SAC Compound Corrosion Test Chamber, Specifications / PVC material welding

| Model | SAC-510 | SAC-748 | SAC-1140 |

| Interior Dimension (L*W*H)mm | 1200x850x500 | 1600x850x550 | 2000x950x600 |

| Exterior Dimension (L*W*H)mm | 1900x1150x1500 | 2300x1150x1550 | 2700x1350x1600 |

| Temperature Range | RT~60℃ | ||

| Test Solution | Pure Water + Sodium chloride(as per Standard) | ||

| Power | 220V 50/60HZ single phase, other voltage power supply can be required to provide | ||

| Air Compression | 40~120 psi(customer self-owned air compressor) |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 1994

- Address: No.1115,Building A,Tianan Digital City,Huangjin Road,Baima,Nancheng

- Contact: David Mo