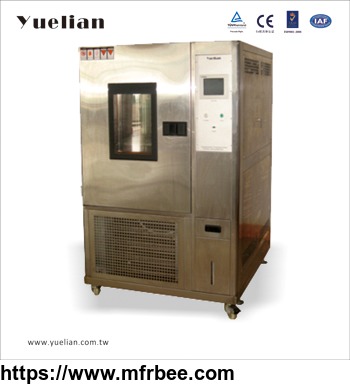

Te Economical Programmable Temperature and Humidity Test Chamber

Product Quick Detail

- FOB Price

- USD $6,500.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China(Mainland)

- Capacity(L)

- 80/150/225/408/800

- Heating Up Speed

- About 3℃/min

- Cooling Down Speed

- About 1℃/min

- Temp. Range

- 0~150℃, -20~150℃, -40~150℃

- Packaging

- 1 set each plywood case

- Delivery

- 30 Days

Specifications

Purpose

The programmable temperature and humidity test chamber, known as environmental chamber, is designed for testing the capability of heat-endurance, cold-endurance, dryness-endurance, and humidity-endurance. It is suitable for the industries of electron, electrical equipment, vehicle, metal, chemistry, building materials, luggage, adhesion tape, printing, packaging, etc.

Feature

1.Appearance: high-texture appearance, arc shape body, and matte fringe processing of surface, planar non-reactive handles, easy operation, safe and reliable.

2.View window: rectangle complex layers of glass view window can be used for observation specimen when doing testing. With anti-sweat heater unit of the window can prevent water vapor condensing water droplets, and high-brightness PL fluorescent lamp keeps box lighting.

3.Water supply system: with external connected water supply system, convenient to humidification and water supply, and automatic recycling and use.

4.Compressor: The compressor circulation system is made in China. it is more effective to remove condenser tube and capillary lubricants, and it adopts environmental refrigerants (R404,A).

5.Control Mode: adopt smart PID+SSR/SCR forward and inverse two-way synchronization output, containing advanced slope control logic.

6.Controller: The controller, with multi-stage program editing temperature and humidity, adopts touch screen made in China.

7.System Capacity: can login multi-section, sections can be divided freely, program can be interrelated freely.

8.Circulation Setting: can operate multi-circulation.

9.Safety Detector: 15 items of full-function system detects, ensure the safety of machine ope

ration, and can automatic display failure time, items and resolved method

| Model | TE-80 | TE-150 | TE-225 | TE-408 | TE-800 |

| Interior Dimension (W×H×D)CM | 40×50×40 | 50×60×50 | 50×75×60 | 60×85×80 | 100×100×80 |

| Exterior Dimension (W×H×D)CM | 93×131×81 | 103×141×91 | 108×162×112 | 117×172×132 | 160×187×132 |

| Capacity(L) | 80 | 150 | 225 | 408 | 800 |

| Heating Up Speed | About 3℃/min | ||||

| Cooling Down Speed | About 1℃/min | ||||

| Temp. Range | 0~150℃, -20~150℃, -40~150℃ | ||||

| Temp. Uniformity | ±1℃ | ||||

| Humidity Uniformity | ±2.5% | ||||

| Temp. Stability | ±0.1℃ | ||||

| Humidity Stability | ±2.5%RH | ||||

| Humidity Range | 20%~98%RH | ||||

| Programmable Mode | Use high stability platinum temperature resistant materials, LCD Chinese & English touch-screen | ||||

| Heating System | SUS#304, stainless steel heater | ||||

| Humidification System | Surface evaporative type, enclose protection of hydropenia, interrupt of power supply and superheat for humidifier. | ||||

| Dehumidification System | Frozen & latent heat dehumidification method | ||||

| Cooling System | Adopt unitary type full-closed air-cool refrigeration system | ||||

| Water Supply System | Circulating water supply system, together with hydropenia warning device | ||||

| Inner & Outer Material | SUS#304, stainless steel of whole machine | ||||

| Insulation Material | Rock wool and rigid PU foam thermal insulation | ||||

| Safety Device | Breaker, compressor overload, ultra-temperature, power failure, temperature limit protection and fault alarm | ||||

| Temp. & Humidity Regulation | Balance adjustment temperature & humidity method | ||||

| Standard Accessories | Automatic demist glass window, 2 sets of adjustable upper and lower interlayer, test holes, chamber lamp, mobile wheels | ||||

| Optional Accessories | Grapher | ||||

| Power | AC220V/380V±10%,50/60Hz |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 1994

- Address: No.1115,Building A,Tianan Digital City,Huangjin Road,Baima,Nancheng

- Contact: David Mo