Metal Wire Gauze Structured Packing - a Quality Structured Packing

Specifications

Metal Wire Gauze Structured Packing with High Separation Rate

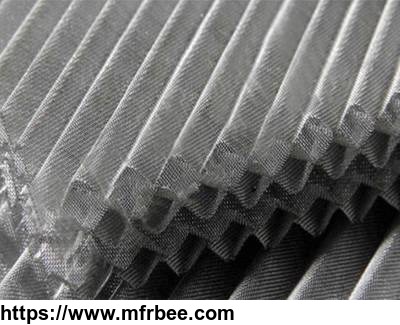

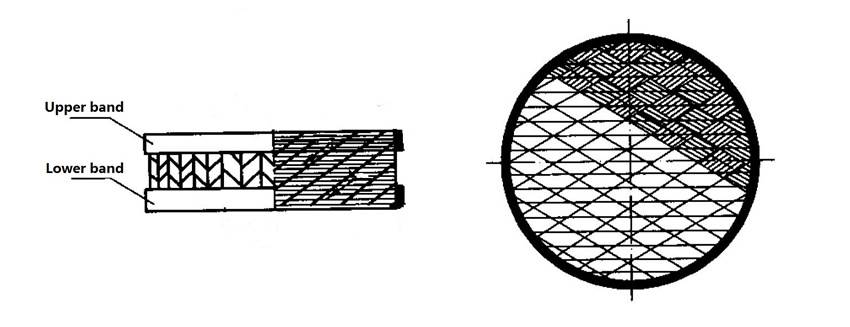

MWGSP-01: Metal wire gauze structured packing is a universal type of packing composed by several mesh plate corrugated sheets.

Metal wire gauze structured packing is an universal type of packing composed by several mesh plate corrugated sheets which are vertical arranged in disks. Instead of being welded, metal wire gauze structured packings are fixed by being nailed or being ringed to adhere to the walls. Its structure can not only change the distribution of liquid, but also increase the transfer efficiency.

The key advantage of wire gauze structured packing is the high separation efficiency even at very small liquid loads along with its low pressure drop and small liquid hold-up, making it very suitable for distillation of thermally sensitive products.

MWGSP-02: Metal wire gauze structured packing has high separation rate.

| Model | Theoretical plate number (1/m) | Specific surface area (m2/m3) | Void volume (m3/m3) | Pressure drop (Pa/m) | Fluid load m3/(m2·h) | Biggest F factor (Pa0.5) |

|---|---|---|---|---|---|---|

| MWGSPS-1 | 0.3 - 1 | 125 | 0.987 | 140 | 0.5 - 100 | 3.5 |

| MWGSPS-2 | 1 - 1.5 | 125 | 0,987 | 200 | 0.5 - 100 | 3 |

| MWGSPS-3 | 1.6 - 2 | 250 | 0.975 | 180 | 0.5 - 100 | 3.1 |

| MWGSPS-4 | 2 - 3 | 250 | 0.957 | 230 | 0.5 - 100 | 2.6 |

| MWGSPS-5 | 2.3 - 3 | 350 | 0.965 | 220 | 0.5 - 80 | 2.3 |

| MWGSPS-6 | 3 - 4 | 350 | 0.965 | 280 | 0.5 - 80 | 2.2 |

| MWGSPS-7 | 3 - 4 | 500 | 0.957 | 250 | 0.5 - 60 | 2.3 |

| MWGSPS-8 | 4 - 5 | 500 | 0.957 | 300 | 0.5 - 60 | 2 |

Features

Metal wire gauze structured packing is a type of structured packing which has great flux, high separation rate, low resistance, low pressure drop, low cost and good anti-plugging performance.

MWGSP-03: Metal wire gauze structured packing has good anti-plugging performance.

MWGSP-04: Metal wire gauze structured packing is usually packed in carton boxes.

Application

Metal wire gauze structured packing has a wide application in the purification, extraction, distillation, cooling and many other possess in the chemical, petrochemical, metallurgic, pharmaceutical and light industry, etc.

Package

- Banded with stainless steel belts.

- Packed with carton boxes & wooden boxes.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Americas

- Founded Year: 1996

- Address: East Industrial Zone, Anping, Hebei, China.

- Contact: qiang Li