FZB506B EDGE BANDER

Product Quick Detail

- Warranty

- 1 year

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- STANDARD SEAWORTHY PACKAGE

- Delivery

- 20 Days

Specifications

APPLICATION

Adopt the linear sealing of PVC,wood plank and veneer etc

1.Using imported quality engines and electric components.

2.Serialized products,a wide range of selection by customers.

3.High precision and effciency

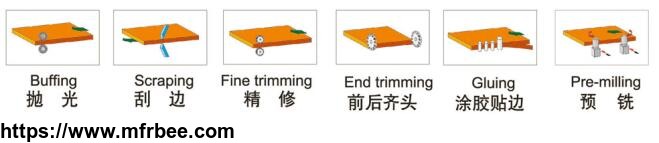

DETAILS SHOWS

1.The glue mechanism adopt a special structure to gelatinize the plates and coating matenals uniformly ,ensure a more solid conglutination.

2.End-trimming mechanism through a precise guide track movement,adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

3.Fine Trimming Unit,with two individual high frequency motors,trim the exceeding edge on the top and bottom side of the panel, ensure the top and bottom side of the edge smooth and even.

4.Scraping unit for a perfect finishing of the applied edge.

5.The buffing device adopt the board processed by cotton polishing wheel,by end-polishing to make a more smooth surface.

CONFIGURATION FORM

| Pre-milling | / |

| Gluing | • |

| End trimming | • |

| Rough trimming | • |

| Fine trimming | • |

| Profiling unit | / |

| Scraping | • |

| Buffing | • |

| Grooving | optional |

MAIN TECHNICAL DATA

| Motor power | 10.48kw |

| Overall size | 4600*1100*1600mm |

| Feed speed | 12~20m/min |

| Panel thickness | 10~60mm |

| Edge banding tape thickness | 0.4~3mm |

| Panel width | ≥40mm |

| Working air pressure | 0.8MPa |

| Weight | 2300kg |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Africa,Emerging Markets,Middle East,Oceania

- Founded Year:2014

- Address:Woodworking Industrial park,Qingdao,China

- Contact:Ann wei

Other products from QINGDAO UNITED ASIA INDUSTRY CO,LTD

Relate products of FZB506B EDGE BANDER

FZB403 SEMI AUTOMATIC EDGE BANDER FEATURES 1.The glue mechanism adopt a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination. 2.Fine Trimming Unit ,with two individual high frequency motors , trim the exceeding edge on ...

FZB505 EDGE BANDER APPLICATION Adopt the linear sealing of PVC, wood plank and veneer etc. 1.Using imported quality engines and electric components. 2.Serialized products, a wide range of selection by customers. 3.High precision and efficiency. DETAILS SHOWS FEATURES 1.The glue ...